Manufacturing

Flexible automated manufacturing strategies

To meet the worldwide benchmark for efficiency, we maintain production 24 hours a day, 7 days a week! This is a great challenge and, at the same time, an indicator of our competitiveness.

We develop and implement new technological and production strategies for our manufacturing in cooperation with our partners – the leading machine producers in the world.

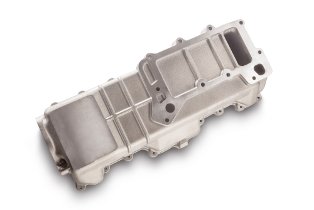

Flexible manufacturing of part variants

Flexible planning and scheduling of all operating resources and machines from the very beginning allows for a quick response if there is a need for production changes or to compensate for constraints in capacity.

Flexibility characterises every level of production and can be seen, among other places, in lean manufacturing structures with a flat hierarchy.

Our employees and executives are characterised by a high sense of commitment, flexible thinking and the willingness to respond quickly to new requirements to find new solutions.

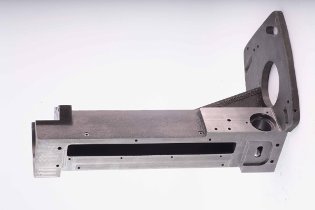

Uncompromising expertise and process reliability

For all products, process reliability is a challenge we face every day! To achieve our goals, we use the latest production equipment with a maximum of process reliability.

We combine consistent and comprehensive automation for maximum possible precision and efficiency with creative and committed employees who are ready to make optimal use of this high level of automation.

All components produced are inspected during the manufacturing process according to the inspection parameters and at intervals predetermined by the customer. This inspection represents a reliable tool for manufacturing optimisation and ensures our long-term reputation for high-quality standards.